BlacksmithingMetal

Blacksmithing 101: How to Start Blacksmithing

By Kristin Arzt

Introduction to Blacksmithing: Understanding the Fundamentals

Are you ready to learn how to start blacksmithing? Here, we are going to walk you through exactly what you need to start blacksmithing, either in our smithy or in your backyard (that’s right, you can—with some effort—set up your own smithy at home). Let’s start with the basics: What is a blacksmith and what is blacksmithing?

What is blacksmithing?

Blacksmithing is the art of forging metal using tools like a hammer and an anvil to make objects, like hinges, nails, hammers, and more. It was a common practice before the industrial revolution when most towns had their own town blacksmith shop, also known as a “village smithy.” In the late 1800s, factories and mass-production reduced the demand for smithed tools and hardware. It is regaining popularity as blacksmiths become more interested in forging their own tools, and modern blacksmith guilds offer support, education, and a sense of community around this growing niche. The art of blacksmithing and bladesmithing, in particular, has enjoyed a resurgence in recent years. Industrial art schools like The Crucible work to increase access to blacksmithing forges and training programs and shows like Forged in Fire bring additional interest and understanding of the art form.

What is a blacksmith?

A blacksmith is a metalsmith who forges metal using tools like a hammer and an anvil to repair and make tools, ornamental objects, hardware, and more.

Quick history of blacksmithing

The blacksmithing industry has changed greatly over the last 200 years, from a necessary skill to an artisanal craft. The time before the industrial revolution was a golden age of American blacksmithing due to the demand for metalwork in newly developing communities. Blacksmiths created essential tools and hardware for building homes and fine-tuning transportation, like wagons and horses.

In the late 1800s, mass production allowed for faster and cheaply made iron products, which threatened blacksmiths’ line of work. Blacksmiths then began to focus their attention on shoeing horses and repairing wagons. As wooden wheels were phased out, forged iron wagon wheels became more reliable for transport. By carving out their expertise, smiths maintained a level of prestige as skilled tradesmen within the transportation industry.

Today, modern blacksmiths create artisanal work and keep traditional techniques alive. The fundamentals of blacksmithing remain greatly unchanged in the last 200 years, with some modern improvements to advancements in tools, like power hammers and angle grinders.

Over the past 20 years, the popularity of artisanally-made goods has increased. Blacksmiths can increase their reach outside of their immediate communities through an online presence. Independent blacksmiths are no longer confined to antique restorations and renaissance fairs and are empowered to sell unique works of art to customers regardless of geography.

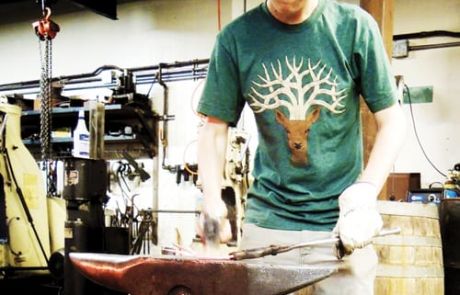

Understanding the fundamentals of blacksmithing

How to start blacksmithing

There are blacksmithing guilds located all over the world, with many regional and state blacksmith associations located throughout the United States. Many of the guilds have local meetups, classes, and job boards. Through your local community of blacksmiths, you can seek out the classes appropriate for your level, apprenticeships, commissions, and more. The Crucible offers a wide variety of classes in our Blacksmithing Department, and also fosters a community of students, teachers, and master smiths in our smithy.

Blacksmithing FAQs

How much money do blacksmiths make?

Blacksmiths that work in structural metal fabricating make an average of $40,000 a year. Self-employed blacksmiths may make more or less, depending on how much work they have and what they charge as independent artists.

What’s the best way to learn blacksmithing?

Blacksmithing comes with its share of risks and dangers. It is your safest and least expensive option to learn blacksmithing from a professional blacksmith in a class.

Can I learn blacksmithing at home?

Once you understand the fundamentals and have learned from a professional blacksmith, it is possible to set up your own smithy at home for around $500 if you source used equipment.

What do you need to start blacksmithing?

We suggest you get started by learning from a professional blacksmith in a class. Once you have an understanding of the fundamentals and safety precautions, you might set up your own blacksmith shop at home. You can gather up the necessary tools and safety equipment, including a forge, anvil, pair of tongs, and hammer. This can be an expensive undertaking, so look for these tools used at farm auctions or within your local blacksmithing guild. Make sure to always wear natural fiber clothing, safety goggles, a mask, gloves, and ear protection when working in the blacksmith shop.

Is blacksmithing easy?

Beginning blacksmithing takes commitment, time, and practice. It is a very physical craft. If you are just starting out blacksmithing, you may develop sore muscles and blisters on your hands after a long day of smithing. Once you have the foundation and fundamentals of blacksmithing down, it should come more easily.

Is blacksmithing dangerous?

Common hazards of blacksmithing include joint injuries and burns. Burn accidents can vary from mild to very serious. Apart from skin burns, the hot sparks that fly during hammering can also be extremely damaging to the eyes. Follow the safety rules of your blacksmith shop and always wear the appropriate safety gear. Since blacksmithing is such a physical craft, make sure you take it slowly in the beginning and take a stretch break whenever necessary. In less common scenarios, blacksmiths can also develop gas poisoning and chemical injuries.